Trestle Table Project

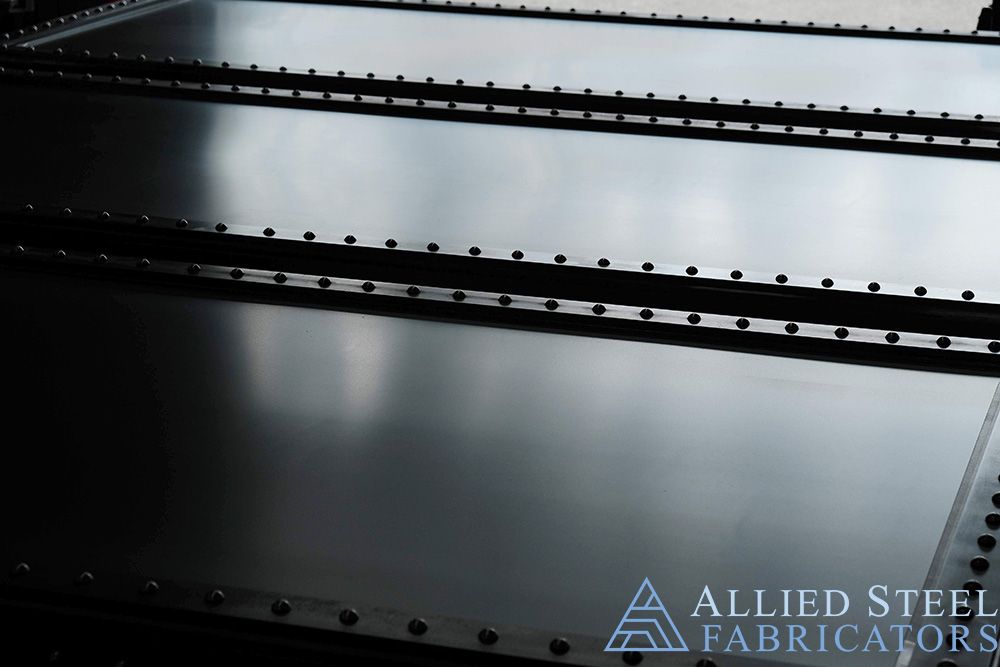

These tables start out with laser cutting 14ga hot roll sheet metal, 3/16” and 3/8” hot roll plate. Once cut, the 3/16” parts are formed and then TIG welded to create the inner structure of the table. The 3/8” pieces are then attached via 308 steel domes rivets and MIG welded in place to increase the table’s strength. Once all of the rivets are welded a 14ga hot roll sheet metal top is added to the table with six angle supports. Each table leg gets an adjustable nylon leveler to protect the floor from its weight of almost 475 pounds. While not pictured, these tables can be modified to accept a glass top to make them more suitable as a dining table.